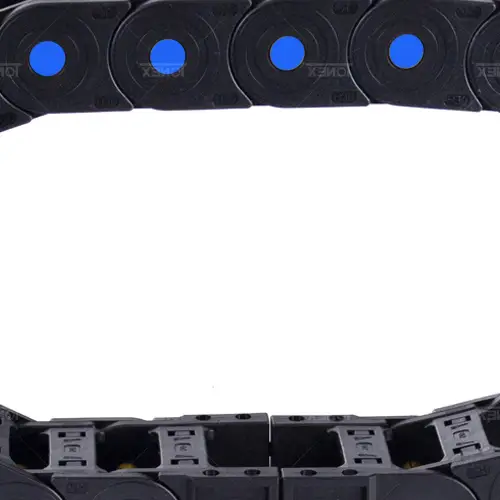

China Standard Flexible Conveyor Plastic Chain for Manufacturer Electronic Industrial with POM PA6 Material 12v Air Compressor

Our China Standard Flexible Conveyor Plastic Chain is designed specifically for manufacturers in the electronic industrial sector. Made with high-quality POM PA6 material, this chain offers excellent durability and reliability. With a 12v air compressor, it ensures efficient performance for various applications.

Product Description

Our China Standard Flexible Conveyor Plastic Chain is manufactured according to GB, ISO, ANSI, and DIN standards. It is available in two types: Standard A and Standard B precision roller chain, conveyor chain. We also offer special chains with accessories, welding chains, leaf chains, and sprockets to meet specific requirements.

For easy identification, this chain comes in various ANSI chain numbers such as 40, 50, 60, 80, 100, 120, 140, 160, 180, 200, and 240. It is also available in C40, C50, C60, C80, C100, C120, C140, and C160 chain numbers. In addition, we provide DIN/ISO chain numbers including 08A, 10A, 12A, 16A, 20A, 24A, 28A, 32A, 36A, 40A, and 48A, as well as C08A, C10A, C12A, C16A, C20A, C24A, C28A, and C32A chain numbers.

Our China Standard Flexible Conveyor Plastic Chain finds applications in various industries including food processing, pharmaceutical and chemical industries, electronics, machinery, household appliances, automotive manufacturing, metallurgy, and sewage treatment.

Product Parameters

| Standard | GB, ISO, ANSI, DIN |

| Type | Standard A and standard B precision roller chain, conveyor chain; special chain with accessories, welding chain, leaf chain and sprocket |

| ANSI chain No. | 40, 50, 60, 80, 100, 120, 140, 160, 180, 200, 240; C40, C50, C60, C80, C100, C120, C140, C160; |

| DIN/ISO chain No. | 08A, 10A, 12A, 16A, 20A, 24A, 28A, 32A, 36A, 40A, 48A; C08A, C10A, C12A, C16A, C20A, C24A, C28A, C32A; |

| Application | Food processing, pharmaceutical and chemical industries, electronics, machinery; household appliances, automotive manufacturing, metallurgy, sewage treatment |

| Series | A series, B series |

More Products

Advantage

Certifications

DETAILS ABOUT CHINAMFG CHAIN

Exhibition

Workshop

Application

Packaging Details

Shipping

At EVER-POWER GROUP, we offer a wide range of industrial products. In addition to our China Standard Flexible Conveyor Plastic Chain, we specialize in supplying agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on providing high-quality products at competitive prices, along with exceptional customer service. We welcome custom drawings and samples to meet specific requirements.

FAQ

1. Can you provide customization services for the China Standard Flexible Conveyor Plastic Chain?

Yes, we offer customization services for our China Standard Flexible Conveyor Plastic Chain. We understand that different applications may require specific specifications, and our team is ready to assist you in meeting your unique requirements.

2. What certifications do your products have?

Our products meet various industry standards and certifications, ensuring their quality and reliability. We hold certifications such as ISO and GB, which validate the performance and compliance of our China Standard Flexible Conveyor Plastic Chain.

3. How long is the lead time for your China Standard Flexible Conveyor Plastic Chain?

The lead time for our China Standard Flexible Conveyor Plastic Chain is typically 35 days after the order is confirmed. However, during low seasons and for certain items, we can provide a lead time of 30 days. Please note that during new year and hot seasons, the lead time may extend up to 45 days.

4. Do you provide samples for testing purposes?

Yes, we offer samples for customers who require confirmation before placing an order. Our sample policy includes the following:

- All samples are free of charge, with a maximum value not exceeding USD 100.

- The courier cost for the first-time sample sending will be borne by the consignee. Please provide your FedEx, UPS, DHL, or TNT account for prompt shipment.

- The first-time courier cost will be deducted from the contract value of the trial cooperation, ensuring a smooth and cost-effective process.

5. How can I contact EVER-POWER GROUP for inquiries and orders?

You can reach us through our website or contact our sales team directly. We are available to answer any questions, provide further information, and assist you with placing orders. Our team is dedicated to ensuring a seamless experience for our customers.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Flexible Chain

Flexible chains offer several performance characteristics that make them highly versatile and suitable for various applications.

1. Superior Flexibility: The key feature of flexible chains is their ability to bend and twist without losing their strength. This allows for easy installation and smooth operation in complex and tight spaces.

2. High Load Capacity: Despite their flexibility, flexible chains are known for their remarkable load-bearing capacity. They can handle heavy loads and provide reliable performance under demanding conditions.

3. Noise Reduction: Flexible chains are designed to minimize noise during operation. This makes them ideal for applications where noise reduction is crucial, such as in automotive and industrial machinery.

4. Wear and Corrosion Resistance: These chains are built to withstand wear and corrosion, ensuring long-lasting performance and reducing maintenance requirements.

Types and Characteristics of Flexible Chain

There are various types of flexible chains available, each with its own unique characteristics.

1. Plastic Flexible Chains: Made from durable plastic materials, these chains are lightweight and offer excellent corrosion resistance. They are commonly used in conveyor systems and packaging machinery.

2. Stainless Steel Flexible Chains: These chains are highly resistant to corrosion and can withstand high temperatures. They are often used in food processing, pharmaceutical, and chemical industries.

3. Anti-Static Flexible Chains: Designed to eliminate static electricity, these chains are suitable for applications in electronic assembly and cleanroom environments.

4. Magnetic Flexible Chains: These chains are equipped with magnetic properties, making them ideal for conveying ferrous materials in the automotive and manufacturing industries.

Advantages of Flexible Chains Made of Different Materials

The choice of material for flexible chains can greatly impact their performance and suitability for specific applications.

1. Plastic Flexible Chains: They offer excellent chemical resistance, are lightweight, and cost-effective. They are commonly used in applications where weight reduction is crucial.

2. Stainless Steel Flexible Chains: These chains are highly durable, corrosion-resistant, and can withstand high temperatures. They are suitable for applications in harsh environments.

3. Anti-Static Flexible Chains: These chains prevent the buildup of static electricity, ensuring the safety of sensitive electronic components and equipment.

4. Magnetic Flexible Chains: They enable efficient handling and transportation of ferrous materials, improving productivity in manufacturing processes.

Application of Flexible Chain

Flexible chains find extensive use in various industries due to their versatility and reliable performance.

1. Automotive Industry: Flexible chains are used in conveying systems, automotive assembly lines, and engine components.

2. Industrial Machinery: They are employed in packaging machinery, conveyor systems, and robotic applications.

3. Agricultural Equipment: Flexible chains are utilized in harvesting machines, grain elevators, and irrigation systems.

4. Construction Equipment: They play a crucial role in concrete mixers, excavators, and lifting equipment.

5. Textile Industry: Flexible chains are used in textile machinery, such as spinning machines and looms.

The wide application of flexible chains in these fields highlights their value and significance in various industries.

Future Development Trends and Opportunities of Flexible Chain Products

The future of flexible chain products looks promising, with several trends and opportunities emerging in the industry.

1. Lightweight Materials: The demand for lightweight chains is increasing, driven by the need for energy efficiency and reduced environmental impact.

2. Advanced Coating Technologies: The development of advanced coatings will enhance the wear resistance and durability of flexible chains, extending their lifespan.

3. Automation and Robotics: The growing automation trend in industries will drive the demand for flexible chains in robotic applications.

4. Sustainable Manufacturing: The focus on sustainability will lead to the development of eco-friendly materials and manufacturing processes for flexible chains.

These trends present significant opportunities for innovation and growth in the flexible chain industry, with a potential for improved performance and expanded applications.

How to Choose a Suitable Flexible Chain

To choose a suitable flexible chain, several aspects need to be considered:

1. Determine Application Requirements: Identify the specific needs of your application, including load capacity, speed, and environmental conditions.

2. Identify the Type of Chain: Understand the different types of flexible chains available and select the one that best suits your application requirements.

3. Select the Chain Material: Consider factors such as corrosion resistance, temperature tolerance, and chemical compatibility when choosing the material for your flexible chain.

4. Consider the Chain Dimensions: Ensure that the chain’s length, width, and pitch are appropriate for your application.

5. Check Compatibility with Sprockets: Verify that the flexible chain is compatible with the sprockets or pulleys used in your system.

By carefully analyzing these aspects, you can choose a flexible chain that will provide optimal performance and longevity for your application.

Summary

In summary, flexible chains offer superior flexibility, high load capacity, noise reduction, and wear and corrosion resistance. They come in various types and materials, each with its own advantages. The application of flexible chains in the automotive industry, industrial machinery, agricultural equipment, construction equipment, and textile industry showcases their value in diverse fields. The future of flexible chain products holds promising trends and opportunities, such as lightweight materials and advanced coatings. By considering application requirements, chain type, material, dimensions, and compatibility with sprockets, you can select a suitable flexible chain that meets your needs.

Author: Dream